Measuring devices

The quality of press brake bending is becoming increasingly important.

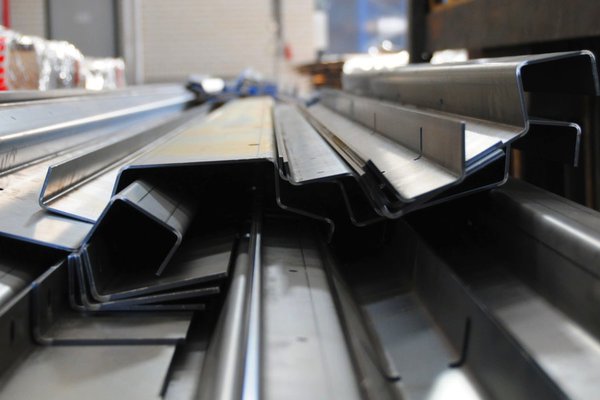

On our bending department we operate 6 Safan Darly “new generation” press brakes. Thanks to NC controlled measuring devices we assure the highest accuracy in angle bending. To become more flexible but also to have more capacity, Snijtech has invested in 2 new press brakes.